Your basket is currently empty!

Connecting the Unconnectable: How Multi-Connectivity Transformed Industrial Automation

In the world of industrial automation, innovation depends on reliable connectivity. Real-time machine monitoring, predictive maintenance, and asset tracking all depend on seamless data flow – but what happens when your operations span wildly different environments, each with its own connectivity challenges?

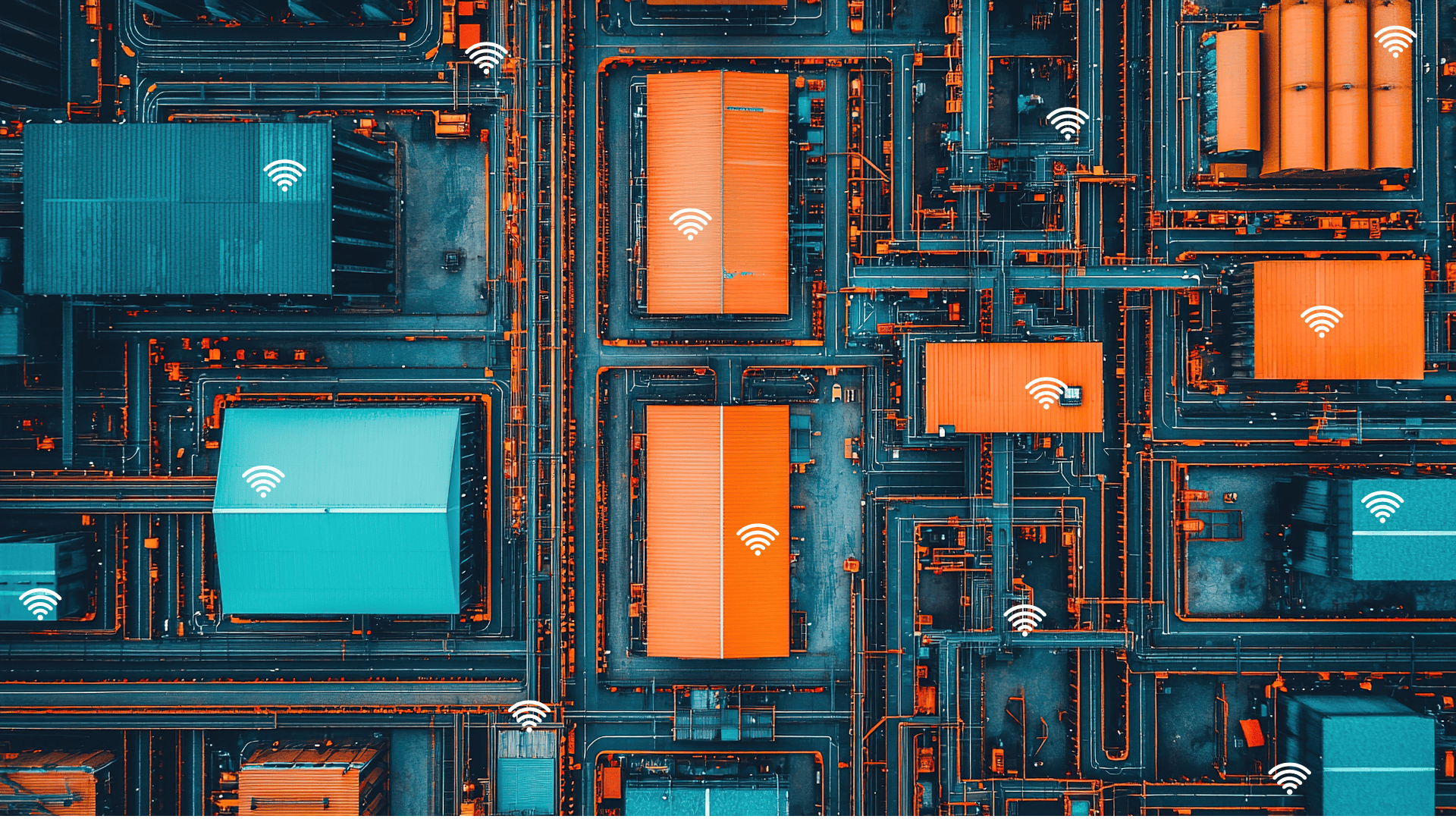

This was the exact dilemma faced by a manufacturing company working to modernize its operations across multiple sites. Their facilities ranged from indoor factory floors saturated with Wi-Fi and Bluetooth signals to sprawling outdoor areas where only long-range, low-power networks could reach.

The Connectivity Challenge

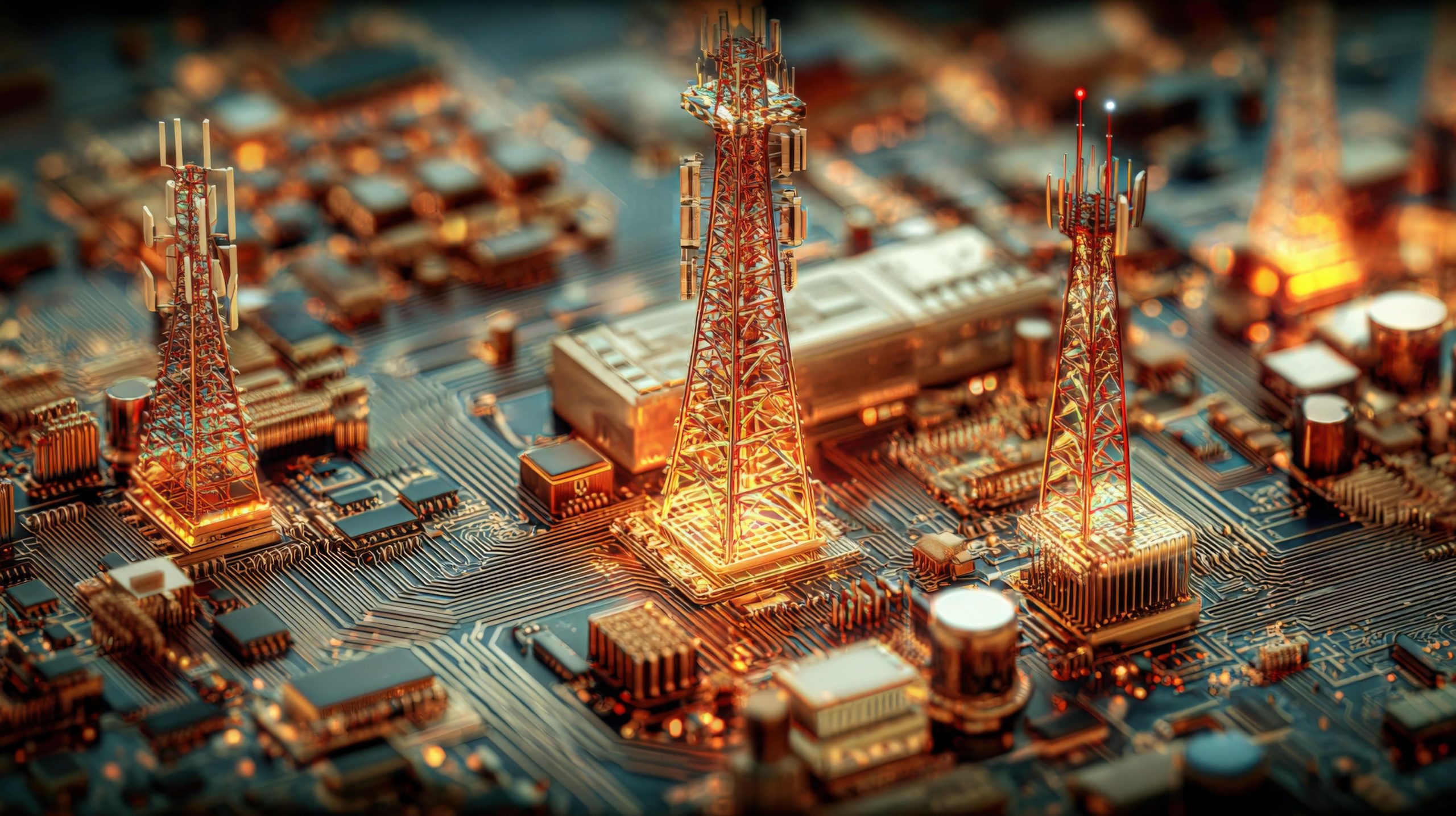

Inside the factories, Wi-Fi and Bluetooth Low Energy (BLE) offered fast, short-range communication ideal for sensor networks and machine-to-machine interactions. However, these technologies quickly lose effectiveness outdoors or across large industrial campuses. For the company’s remote equipment and assets, they needed a solution that could reliably transmit data over long distances with minimal power consumption.

Traditional approaches often meant deploying separate systems for indoor and outdoor environments, leading to fragmented data, complex management, and increased costs. The company needed a unified IoT solution that could adapt to diverse network conditions and provide continuous, reliable connectivity, no matter where their machines or assets were located.

Enter the SG Wireless F1 Smart Module

The breakthrough came with the SG Wireless F1 Smart Module, a compact IoT development platform designed with multi-connectivity at its core. Supporting BLE, Wi-Fi, LoRaWAN, and 4G LTE (CAT-M1/NB-IoT), the F1 module offers unparalleled flexibility to connect devices across any environment.

This meant that whether a sensor was deep inside a factory, roaming a large outdoor yard, or operating in a remote site, the same module could maintain uninterrupted data flow by intelligently switching between or combining networks.

Accelerating Development with MicroPython and Zero-Touch Provisioning

Versatile connectivity was just one aspect of the solution. The F1 Smart Module’s support for MicroPython enabled the company’s engineering team to rapidly prototype and customize firmware. MicroPython’s interactive coding environment allowed developers to test and iterate in real time, drastically reducing development cycles.

Additionally, zero-touch provisioning simplified the deployment and remote management of thousands of sensors and trackers across multiple sites. This automated onboarding process minimized manual setup, reduced errors, and allowed the company to scale their IoT rollout quickly and efficiently.

Real Results: From Data Gaps to Data-Driven Decisions

With the F1 Smart Module powering their IoT devices, the manufacturer unlocked several key benefits:

- Reliable Real-Time Monitoring: Continuous data streams from machines and equipment provided live insights into operational status, enabling faster responses to issues.

- Predictive Maintenance: Early detection of anomalies through real-time data reduced unplanned downtime and extended equipment life.

- Enhanced Asset Tracking: Accurate location and usage data improved asset utilization and inventory management across all sites.

- Scalable, Future-Proof Deployment: The multi-network connectivity and cloud integration supported seamless scaling from pilot projects to full production without connectivity gaps or management headaches.

Why Multi-Connectivity Matters in Industrial IoT

This success story highlights a critical lesson for industrial IoT deployments: one size does not fit all. Industrial environments are complex and varied, and connectivity needs can change dramatically from one location to another. A multi-connectivity approach ensures that devices stay connected, data stays flowing, and operations stay optimized, regardless of where they are.

By embracing flexible connectivity, rapid prototyping, and streamlined deployment, companies can overcome traditional IoT barriers and unlock the full potential of smart manufacturing.

Is Your Industrial IoT Ready for Multi-Connectivity?

If your organization is grappling with connectivity challenges across diverse environments, it might be time to rethink your approach. The right combination of technologies, like the SG Wireless F1 Smart Module, can transform fragmented systems into unified, scalable IoT solutions.

At SG Wireless, we are passionate about empowering industrial innovators to connect the unconnectable – turning complexity into opportunity, and data into action. Ready to explore multi-connectivity for your industrial IoT projects? Reach out to learn how we can help you build smarter, more resilient operations.